Flame arrestors are imperative protection gadgets in industrial settings, playing a vital function in stopping the ignition of flammable gases and vapors. These gadgets aren’t only pivotal in safeguarding centers from fires and explosions but also make contributions drastically to environmental protection.

This article delves into the diverse elements of flame arrestors, exploring their kinds, capabilities, technological improvements, and their crucial function in keeping safety and sustainability in industries global.

Table of Contents

The Critical Role of Flame Arrestors in Safety and Protection

Flame arrestors are important safety devices designed to save you from the propagation of flames in numerous systems, in particular in underground utilities and storage tanks. These devices are essential in mitigating heart risks and stopping explosions, ensuring the protection of both personnel and infrastructure.

Understanding the Design and Function of Flame Arrestors

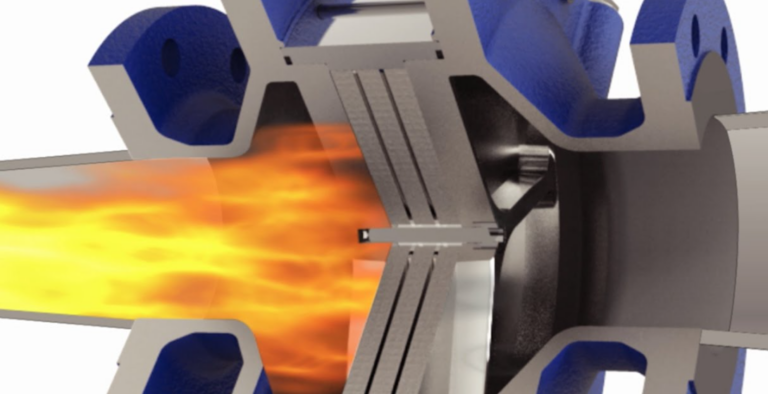

Flame arrestors are usually constructed using metal plates, displays, or mesh, creating a tortuous course that disrupts and cools down the flame, preventing the ignition of flammable gases or vapors.

This flame quenching mechanism is critical in extinguishing flames earlier than they could ignite surrounding materials. The layout lets in for the glide of gases or vapors even as effectively impeding the passage of flames, making them a necessary part of protection systems in various industries.

Diverse Applications and Importance in Industry

Flame arrestors find their programs in various industries, together with oil and gas, chemical processing, and wastewater treatment. They are commonly utilized in pipelines, storage tanks, and different areas where flammable gases or vapors are gift.

By halting the propagation of flames, flame-arrestors play a pivotal function in preventing explosions and subsequent fires, thereby shielding gadget and personnel.

Types and Variations of Flame Arrestors

Flame arrestors come in diverse sorts and designs, each tailored to particular programs and dangers. The most important categories are quit-of-line and in-line flame-arrestors. End-of-line arrestors are used at the open give up of a pipeline or venting machine, more often than not to prevent the propagation of flames into the atmosphere.

In assessment, in-line arrestors are installed within the pipeline device and are designed to save you the spread of flames from one part of the device to every other.

Additionally, there are distinctive designs based totally on the approach of flame quenching, which include crimped steel plates or twine mesh. The choice of the proper type and design of flame arrestor is essential and relies upon on elements just like the nature of the flammable substance, running conditions, and the specific dangers involved.

Installation and Maintenance Best Practices for Flame Arrestors

Proper set up and ordinary preservation are key to ensuring the powerful functioning of flame arrestors. When installing a flame arrestor, it is essential to don’t forget factors which include orientation, region, and compatibility with the present machine.

Incorrect installation can cause decreased effectiveness or even failure of the device. Regular maintenance, inclusive of cleansing and inspection, is important to prevent blockages and to ensure the arrestor stays in appropriate working condition.

Blockages may be resulting from dust, debris, or corrosion and might obstruct the arrestor’s capability to quench a flame. Routine exams and preservation not most effective make bigger the lifespan of the flame arrestor but additionally ensure continuous safety in environments with flammable gases.

Regulatory Standards and Compliance for Flame Arrestors

Flame arrestors must adhere to diverse regulatory requirements and certifications to ensure protection and effectiveness. These requirements, which vary by means of region and enterprise, specify requirements for design, production, and performance.

Compliance with these requirements isn’t only a criminal requirement however additionally a vital thing of operational safety.

Manufacturers and users of flame arrestors need to be aware about and observe applicable requirements together with those set by using the American Petroleum Institute (API), the National Fire Protection Association (NFPA), and other global protection agencies.

Regular audits and certifications are a part of preserving compliance, ensuring that flame-arrestors meet the necessary safety criteria.

Innovations and Technological Advancements in Flame Arrestor Design

The discipline of flame arrestor technology is constantly evolving, with improvements aimed at improving protection and efficiency. Recent advancements encompass the improvement of arrestors with self-cleansing mechanisms and stepped forward heat resistance, which reduce protection requirements and enhance sturdiness.

Additionally, there is a growing fashion in the direction of the integration of clever era in flame arrestors. These smart gadgets can offer real-time tracking and alerts for blockages or malfunctions, bearing in mind spark off reaction and renovation.

Such technological improvements no longer most effective improve the reliability of flame arrestors but additionally make a contribution to usual operational protection in industries in which they may be used.

The Role of Flame Arrestors in Environmental Protection

Flame arrestors play a significant role in environmental protection with the aid of stopping fires and explosions that may result in harmful emissions and ecological harm.

In industries like oil and gasoline, wherein the danger of such incidents is high, flame arrestors are crucial for minimizing the environmental effect. By preventing the unfold of flames, those devices save you the discharge of toxic gases and pollution, contributing to purifier air and a more secure environment.

Moreover, the usage of flame arrestors is often part of a broader environmental control approach, demonstrating a commitment to sustainable and accountable business practices.

Conclusion

Flame arrestors are greater than simply protection additives; they are vital instruments in safeguarding business operations and protecting the surroundings. Their function in stopping the ignition of flammable gases and vapors is crucial in industries wherein even a small spark can cause catastrophic consequences.

The non-stop advancements in flame arrestor technology, inclusive of the mixing of clever functions and advanced design for better performance and reliability, mirror the enterprise’s dedication to safety and innovation.

In conclusion, flame arrestors constitute a crucial intersection of safety, era, and environmental stewardship. Their evolving designs and applications not only meet the needs of present day business operations however additionally align with global efforts towards a greater sustainable and accountable industrial future.