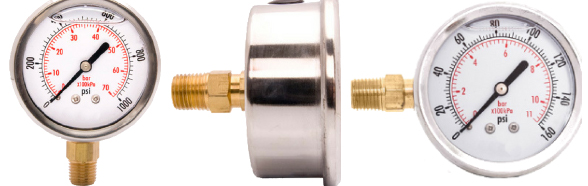

Pressure gauges are devices used to measure the pressure of gasses or liquids in a system. They are essential tools for monitoring and controlling pressure levels in various industrial processes. However, when it comes to installing a pressure gauge, one important consideration is the type of connection it requires.

The connections facilitate the flow of fluid and measure the pressure exerted within a given system. Moreover, pressure gauge connections come in different forms, materials, and sizes to suit different application needs, making them commonplace in various industries. They play a crucial role in maintaining the safety and optimal functioning of the system in which they operate. Understanding the definition and background of pressure gauge connections is essential in their proper selection, installation, and maintenance, ensuring efficient operation and safety.

In this article, we will discuss some common types of pressure gauge connections, including NPT and BSP, and explain their applications.

Table of Contents

NPT Connection

NPT, or National Pipe Thread, is a widely used thread type for connecting pipes and fittings in plumbing, heating, and industrial processes. It is based on the American Standard Taper Pipe Thread standards and has a 60-degree thread angle.

NPT connections are commonly found in pressure gauges designed for use in the United States and Canada. They are also used extensively in industries such as oil & gas, chemical processing, and food & beverage.

BSP Connection

BSP, or British Standard Pipe, is a thread type widely used in Europe, Asia, Australia, New Zealand, and South Africa. It is based on the Whitworth thread standards and has a 55-degree thread angle.

Similar to NPT, BSP connections are commonly found in pressure gauges used in industries such as oil & gas, chemical processing, and food & beverage.

Metric Connection

Metric connections are based on the metric or SI system of measurement and are used in countries that have adopted this standard. They come in various thread types, such as G (BSPP), R (BSPT), and M.

Metric connections are also commonly used in pressure gauges designed for use in industrial processes.

Flanged Connection

Flanged connections consist of two flat faces with bolts securing them together. They are commonly utilized for higher-strain applications where a strong association is required.

Pressure measures with flanged associations can be tracked down in different ventures, including oil and gas, substance handling, and power age.

Tri-Clamp Connection

Tri-clamp connections are a type of sanitary connection used in the food and beverage industry. They consist of two ferrules with a gasket in between that is clamped together using a tri-clover clamp.

Pressure gauges with tri-clamp connections are specifically designed to meet the strict hygiene requirements of the food and beverage industry.

Bottom Connection

Bottom connections are widely used in pressure gauges for applications requiring direct mounting to a tank or vessel. They can come in various thread types, including NPT, BSP, and metric.

Industries that commonly use bottom connections include chemical processing, pharmaceuticals, and water treatment.

Back Connection

Back connections are similar to bottom connections, except the pressure gauge is mounted on the back instead of the bottom. They are commonly used in applications where vertical mounting is preferred.

Pressure gauges with back connections can be found in various industries, including HVAC, refrigeration, and gas utilities.

Center Back Connection

Center-back connections are similar to back connections but have a center-mounted stem instead of an offset one. They are commonly used in applications where space is limited or where the gauge needs to be protected from external damage.

Pressure gauges with center-back connections can be found in industries such as HVAC, refrigeration, and water treatment.

Choosing the Right Connection Type for Your Application

Selecting the right pressure gauge connection type can be challenging, given the vast number of options available. It is essential to consider factors such as the application, fluid compatibility, and installation requirements when choosing a connection type.

Some common considerations include:

- The fluid being measured: certain fluids may require specific materials or thread types for compatibility.

- Pressure levels: higher pressure applications may require stronger connections, such as flanged or tri-clamp.

- Installation requirements: factors like space limitations and mounting options may determine which connection type is suitable.

It is also crucial to ensure proper installation and maintenance of the pressure gauge connection to prevent leaks, avoid damage, and maintain accurate readings. Regular inspection and replacement of worn or damaged connections are essential for maintaining the safety and efficiency of the system.

How to properly Install a Pressure Gauge with Your Chosen Connection Type

1. Gather all the required tools and materials, including pipe sealant tape or thread sealant.

2. Carefully clean and inspect the connection threads on both the gauge and the system.

3. Apply a thin layer of sealant to the male threads of the pressure gauge.

4. Begin threading the gauge into the system by hand, ensuring it is aligned correctly.

5. Use a wrench to tighten the connection further until it is snug.

6. Connect the gauge to the system, ensuring proper alignment and support.

7. Use a wrench to tighten any additional connections necessary.

8. Turn on the system and check for leaks or any abnormal readings from the pressure gauge.

Make sure to constantly choose the suitable association type for your application and follow prescribed establishment and upkeep techniques to drag out the life expectancy of your tension measure. So, presently, you have a superior comprehension of a few normal kinds of strain measure associations, their applications, and how to introduce them appropriately.

Try to pick the right association type for your particular requirements, and consistently focus on well-being in all parts of utilizing pressure checks. Thank you for

FAQ’s

Q: Are there any other types of pressure gauge connections not mentioned?

A: Yes, there are other types, such as push-on connections, weld-in connections, and seal-ring connections.

Q: Can a pressure gauge with one type of connection be converted to another type?

A: In some cases, it is possible to convert the connection type of a pressure gauge. It is best to choose the appropriate connection type from the start.

Conclusion

In conclusion, choosing the right pressure gauge connection type is crucial for the proper and safe operation of industrial processes. Understanding the different types available and their applications can help you make an informed decision when selecting a pressure gauge for your specific needs. Remember to always follow recommended installation and maintenance procedures to ensure the accuracy and longevity of your pressure gauge connections.

So, next time you come across a pressure gauge, you will have a better understanding of its connection type and its purpose. Keep in mind the various factors to consider when selecting a connection type, and always prioritize safety in all aspects of using pressure gauges.