The pharmaceutical industry is crucial for improving and preserving countless lives through creating life-saving drugs. However, the integrity of the pharmaceutical supply chain is continually in danger due to stolen goods, diversion, and imitation of pharmaceuticals, which can harm patient safety.

The Track and Trace System has been designed to address these problems and guarantee the genuineness of pharmaceutical products.

In this detailed blog, we will explore the concept of the Track and Trace in pharma, its components, implementation, benefits, challenges, and impact on patient safety and industry regulations.

Table of Contents

Understanding the Track and Trace System

The Track and Trace System is a comprehensive solution implemented in the pharmaceutical industry to monitor and authenticate the movement of pharmaceutical products throughout the supply chain. This system aims to enhance transparency and traceability, ensuring that every step of a drug’s journey from manufacturer to patient is documented and verified.

Components of the Track and Trace System

To achieve its objectives, the Track and Trace System consists of several essential components:

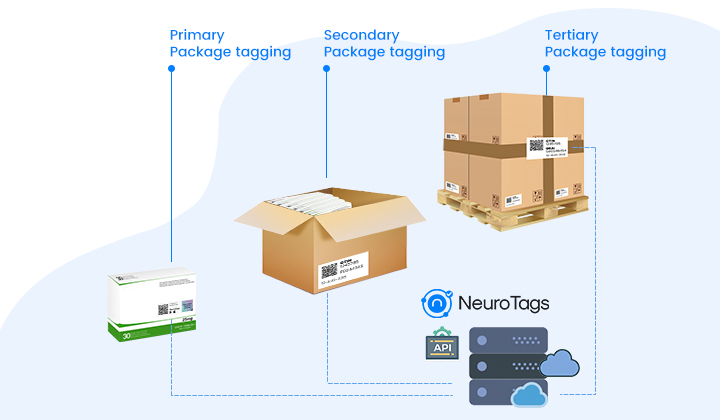

- Serialization: Each pharmaceutical product is assigned a unique serial number or code as its digital fingerprint. Serialization allows for the identification and tracking of products at various points in the supply chain.

- Data Management: A centralized database or platform stores and manages the information associated with serialized products. This database is the backbone of the Track and Trace System, facilitating data sharing and access among stakeholders.

- Barcodes and QR Codes: Serialized products are often labeled with barcodes or QR codes, making it easy to scan and retrieve information about the product’s origin, authenticity, and batch details.

- Scanning and Verification Devices: Various scanning and verification devices, such as handheld scanners or mobile apps, are used by supply chain participants to scan barcodes or QR codes on pharmaceutical products and verify their authenticity.

- Communication Protocols: Secure communication protocols and standards are established to facilitate data exchange between stakeholders, including manufacturers, distributors, wholesalers, and pharmacies.

- Reporting and Alerts: The system generates real-time reports and alerts for any suspicious or irregular activities, helping to detect and prevent counterfeit products from entering the supply chain.

Implementation of the Track and Trace System

Implementing the Track and Trace System in the pharmaceutical industry is a complex and multi-step process that involves various stakeholders. Here is an overview of the critical steps:

- Regulatory Compliance: Pharmaceutical companies must comply with regional and international regulations that mandate serialization and track and trace solutions. Examples include the Drug Supply Chain Security Act (DSCSA) in the United States and the Falsified Medicines Directive (FMD) in the European Union.

- Serialization at Manufacturing: Manufacturers integrate serialization processes into their production lines, assigning unique serial numbers to each product. These serial numbers are often printed on labels or packaging.

- Data Integration: The serialized data is integrated into a centralized database or platform accessible to authorized supply chain participants.

- Distribution and Verification: Pharmaceutical products are distributed through the supply chain, and each stakeholder scans and verifies the products using scanning devices or mobile apps.

- Data Sharing: Real-time data sharing among stakeholders ensures visibility and traceability of products at all stages of distribution.

- Reporting and Alerts: The system generates alerts for suspicious or unauthorized activities, enabling prompt actions to mitigate risks.

Benefits of the Track and Trace System

The implementation of the Track and Trace System in pharmaceuticals offers several significant benefits:

- Counterfeit Prevention: The system is a robust defense against counterfeit drugs, reducing the likelihood of patients receiving substandard or fake medications.

- Patient Safety: The Track and Trace System protects patient health and safety by ensuring the authenticity of pharmaceutical products and preventing potential harm caused by counterfeit or contaminated drugs.

- Regulatory Compliance: Pharmaceutical companies can maintain compliance with evolving regulations and standards, avoiding legal and financial penalties.

- Supply Chain Visibility: The system enhances visibility and transparency across the supply chain, reducing the risk of product diversion and theft.

- Recall Management: In case of product recalls or quality issues, the Track and Trace System enables quick and precise identification of affected batches, minimizing the impact on patients and healthcare providers.

- Improved Efficiency: Automation and data integration improve supply chain efficiency, reducing operational costs and errors.

- Consumer Trust: Increased transparency and safety measures build consumer trust in pharmaceutical products and the industry.

Challenges and Considerations

Despite the many advantages of the Track and Trace System, its implementation poses several challenges and considerations:

- Cost: Implementing serialization and track and trace technology, especially for smaller pharmaceutical companies, can be costly.

- Compatibility: Ensuring compatibility and data exchange among stakeholders and systems can be complex, requiring standardized protocols.

- Data Security: Protecting the sensitive data stored in the centralized database is crucial to prevent unauthorized access and cyber threats.

- Global Variability: Pharmaceutical companies may need to adapt their serialization practices to comply with international regulations, which adds complexity.

- Education and Training: Training all supply chain participants to effectively use the system and interpret alerts is essential for its success.

- Scalability: The system must be scalable to accommodate the increasing volume of pharmaceutical products and evolving supply chain needs.

Impact on Patient Safety and Industry Regulations

The implementation of the Track and Trace System has had a profound impact on patient safety and industry regulations:

- Patient Safety: Patients can now have greater confidence in the authenticity and safety of their pharmaceutical products, leading to better health outcomes.

- Regulatory Compliance: The pharmaceutical industry is better equipped to comply with stringent regulations and quality standards, reducing the risk of non-compliance-related penalties.

- Enforcement: Regulatory agencies have enhanced monitoring and enforcing compliance tools, enabling faster responses to issues and violations.

- Global Standardization: Adopting serialization and track and trace technology has led to international standardization efforts, harmonizing practices across countries and regions.

- Industry Evolution: The pharmaceutical industry has transformed, with increased emphasis on transparency, accountability, and patient-centric approaches.

The Track and Trace System in the pharmaceutical industry represents a significant advancement in ensuring the authenticity and safety of pharmaceutical products. While challenges exist, the benefits of patient safety, regulatory compliance, and supply chain efficiency are substantial.

As the pharmaceutical supply chain continues to evolve, BCI’s Track and Trace System will play an increasingly vital role in maintaining the industry’s integrity, ultimately contributing to better healthcare outcomes for patients worldwide.