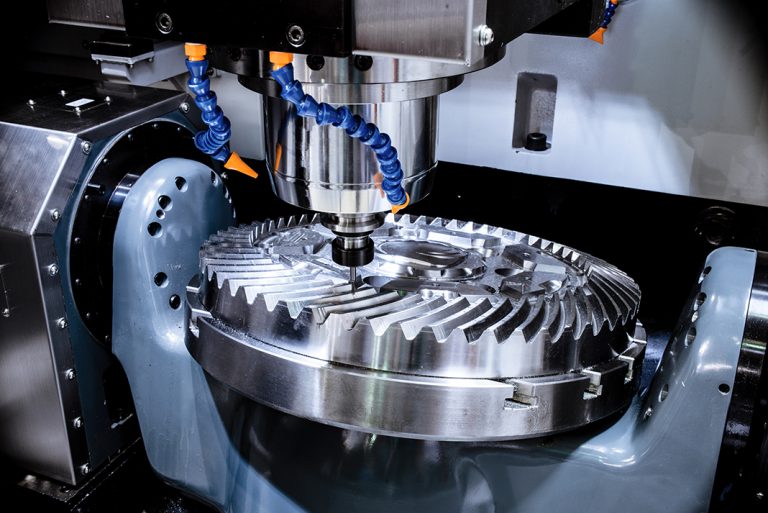

CNC milling is a manufacturing process that uses computer-controlled machines to create objects from metal, plastic, or other materials. These machines are called CNC mills, and they can be used to create a wide variety of objects, including:

– Parts for machinery

– Prototypes for new products

– Customized fittings and fixtures

If you’re looking for an efficient way to create customized metal parts and products, then CNC milling may be the perfect solution for you!

See also : accupro

How do cnc milling works?

In its simplest form, it is the process of using a computer to control the movement of a machine that cuts away material from a larger piece. The computer sends commands to the milling machine which moves according to those instructions, removing small bits of material until the desired shape or profile is achieved.

To begin milling, a three-dimensional design of the desired object is created in a computer program. The design is then converted into a set of instructions, called G-codes, which tell the CNC mill what steps to take in order to create the object.

Once the G-codes have been generated, they are downloaded to the CNC mill, which begins to carve out the object from a block of material. The finished product is then typically cleaned up and polished, before being shipped off to the customer.

CNC milling services is a versatile manufacturing process that can be used to create objects of all shapes and sizes. So if you’re in need of custom parts or products, be sure to give CNC milling a try!

The types of CNC milling

CNC milling services is a machining process suitable for producing high precision, high tolerance parts on prototype, single use and small to medium scale production runs. Although parts are typically manufactured to tolerances between +/ -2 wire and +/ -10 wire, some milling machines can achieve tolerances up to +/ -1 wire or even higher. The versatility of the milling process allows it to be used in a wide range of industries and for a variety of part features and designs, including slots, chamferes, threads and cavities.

The most common CNC milling operations include:

End face milling

Plane milling

Angle of the milling

Forming milling

End face milling

It is the process of milling the end face of a workpiece, typically square or rectangular in shape. The end face is milled flat and perpendicular to the workpiece’s longitudinal axis.

Plane milling

Plane milling is the process of machining a flat surface on a workpiece. The surface can be machined at any angle relative to the workpiece’s longitudinal or transverse axis.

Angle of the milling

Angular milling is the process of machining a part at an angle relative to its longitudinal or transverse axis. The angle can be any value from 0 degrees to 360 degrees.

Forming milling

Form milling is the process of machining a three-dimensional shape into a workpiece. The shape can be anything from a simple slot to a complex contour.

CNC milling offers many benefits over traditional machining methods, including:

Increased accuracy: CNC milling machines are capable of holding tight tolerances, making them ideal for producing high precision parts.

Increased productivity: CNC milling machines can work 24 hours a day, allowing for increased production rates.

Improved quality: CNC milling machines produce parts that are consistent in quality, meaning less time is spent on inspection and rework.

Reduced lead times: CNC milling machines can quickly produce parts, often reducing lead times from weeks to days.

CNC milling is a versatile manufacturing process that can be used to create parts of all shapes and sizes. So if you’re in need of custom parts or products, be sure to give CNC milling a try!

What are the drawback of CNC milling?

Like any manufacturing process, there are also some drawbacks to CNC milling, such as:

– Limited to the size and shape of the material that can be milled

– Requires a high initial investment in equipment and software

– Can be difficult to create complex shapes or designs

Overall, CNC milling is a versatile and efficient manufacturing process that can be used to create high-quality parts and products. So if you’re in need of custom parts or products, be sure to give CNC milling a try! Thanks for reading! We hope this article was helpful in explaining what CNC milling is and how it works. If you have any further questions, please don’t hesitate to reach out to us! We’re always happy to help.