In the fast-evolving and highly competitive business landscape, efficiency is key. Industries are increasingly turning to automated sortation systems to streamline their operations for a competitive edge. These systems have revolutionized how businesses handle sorting tasks, making them faster, more accurate, and cost-effective. If you are wondering if the sortation conveyor system can fit in your field of business and how it can help, you have come to the right place. We will analyze the distinct features and requirements of common industries and then the functions automatic warehouse sorters provide in accordance. Let’s do it.

How does Warehouse Sorting Work Vary among Industries?

The meaning of sortation is to arrange items into specific categories, orders, or groups based on certain criteria. Automated sortation systems find applications in various industries that all differ in needs and challenges to be contemplated. Let’s have a closer look at several of the industries and the way warehouse sorters help them:

- Electronic Manufacturing Industry

In the electrical manufacturing industry, there is a need for efficiency and precision in handling delicate electronic components with varying sizes and shapes. The automated warehouse sortation systems save manufacturers from sorting the parts slowly to find the right one and save the risk of damage to electronic components accidentally along the way. Support in this regard enables increased production efficiency.

- Auto Parts Industry

There is a diverse range of parts in terms of size, weight, and fragility in the auto parts industry, making efficient sorting and identification of various components paramount for production efficiency. By using automated warehouse sorters for easy access, operators can efficiently sort and keep the auto parts according to their size, shape, and other factors. This aids in improved inventory management and simultaneously increases the order fulfillment speed, resulting in a satisfied customer base and better profitability.

- E-commerce Industry

The e-commerce industry has grown significantly in recent years, and hence, excellent order fulfillment processes have taken center stage. However, it is no mean feat to efficiently handle a vast array of products, from small to large, with various order volumes and rapid turnover. E-commerce warehouses, therefore, significantly rely on automated sortation systems to sort the items quickly and accurately before forwarding them for shipment. This guarantees timely and accurate order filling, which ensures that the customers are satisfied since the performance of order accuracy is sustained to prevent a dent in business.

- Omnichannel Logistics Industry

The omnichannel logistics industry means managing inventory and order fulfillment across multiple sales channels, including physical stores, online, and mobile applications. Warehouses can handle orders of miscellaneous products and channels efficiently through automated sortation systems, where the correct products are sorted out and sent to their respective channels quickly. The delivery time improves, the number of mistakes in the order is reduced, and overall, customer satisfaction is enhanced.

What are the Benefits of Automated Sortation Stations?

Automated sortation stations offer numerous benefits that enhance operational efficiency and improve overall business performance. Some of these benefits include:

Increased Efficiency and Accuracy

Automating the sorting process would reduce human errors to a great extent by giving businesses more accuracy. The automated warehouse sortation system uses high technology like barcode scanning and computer vision to identify and sort goods in an exact manner. This essentially saves time and reduces the risk of placing it at the wrong station or giving the wrong shipment.

Optimized Space Utilization

Most of the traditional methods of sorting that are quite uneconomical and inefficient require a lot of floor space. On the contrary, automated sortation systems have been designed to optimize space utilization. This will help companies optimize the space available by reorganizing and compressing items and reducing storage costs, subsequently improving the entire warehouse’s efficiency.

Enhanced Inventory Traceability

The accuracy of records is important for decision efficacy in running the business. The automated sortation systems offer real-time inventory visibility, which is critical in tracking and tracing goods at every point of the sortation process. This promotes inventory accuracy, reduces the number of stockouts, and enhances replenishment of stocks.

Enhanced Throughput

Automated sortation systems allow businesses to handle more items in a short time. They make handling faster without causing any bottlenecks and generally improve service delivery through automation in the sorting process. It allows increased customer demand to be met, order processing times reduced, and hence increasing overall customer satisfaction.

High-Performance Workstations Recommendation

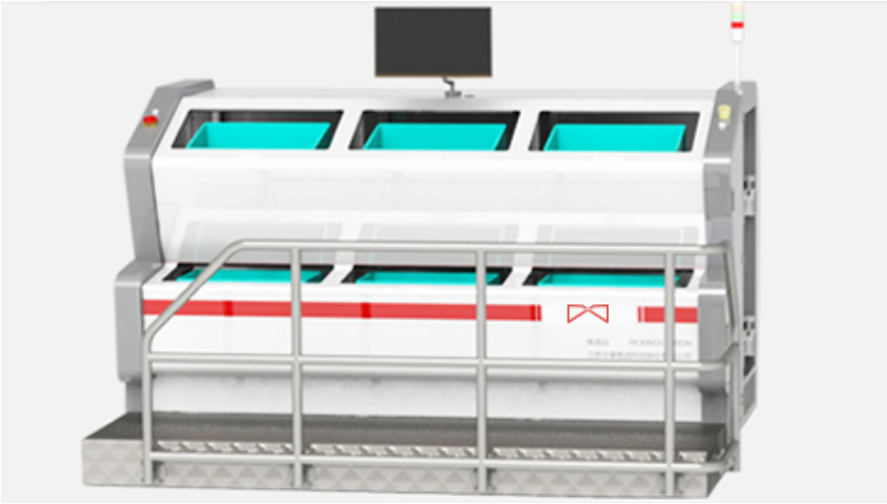

Introducing the PSD310 Double-Layer Sorting Station by HWArobotics – the cornerstone of efficient “goods-to-person” systems! This versatile workstation excels in split picking alongside AS/RS and conveyor systems, making it an invaluable asset for diverse industries such as food, tobacco, medicine, cosmetics, electronics, and more.

Key features:

- Versatile Split Picking: PSD310 meets the demands of multiple varieties and split orders, ensuring precise sorting for enhanced productivity.

- Multi-functional Workstation: Beyond sorting, PSD310 Double-Layer Sorting Station can serve as a comprehensive workstation for receiving, inventory counting, auditing, and various tasks, streamlining your operations.

- Wide Industry Applicability: Suitable for diverse sectors, including electronic manufacturing, auto parts, e-commerce, new retail, and omnichannel logistics, PSD310 is a versatile solution for modern warehouses.

- Efficiency Amplified: The double-layer design optimizes space and workflow, ensuring a seamless and organized sorting process.

Unlock unprecedented efficiency in your warehouse operations with HWArobotics’ PSD310 Double-Layer Sorting Station. It’s not just a sorting station; it’s a powerhouse for optimized workflows. Take your logistics to new heights – invest in PSD310 today and revolutionize your approach to order fulfillment. Elevate your productivity with HWArobotics!

Conclusion

In today’s highly dynamic business world, mastering efficiency is the key to success. Automated sortation systems have become crucial for businesses across diverse industries, revolutionizing sorting techniques and driving operational excellence. This great tool can enhance accuracy levels, optimize maximum utilization space, and trace inventories and throughput for businesses.

HWArobotics stands at the forefront of automated sorting technology, offering cutting-edge solutions like the PSD310 Double-Layer Sorting Station. Our commitment to innovation, efficiency, and customer satisfaction makes us your partner of choice in streamlining your business. Take the first step in efficiency mastery in your industry. Discover how warehouse sortation systems can turn your business around, unlocking the potential for growth and success.