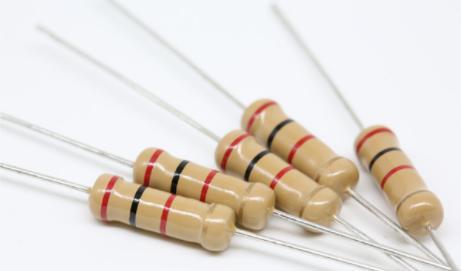

In electrical or electronic circuits, one of the most regularly utilized “passive devices” is a resistor. On account of its great many applications, they exist in various assortments. Contingent upon the sort of obstruction they give, these devices are normally named fixed or variable resistors. In any case, whether the obstruction is fixed or variable, the design is unique. So we named them as per their design type. Carbon film resistors are one sort of obstruction.

Table of Contents

What is a Carbon Film Resistor?

It is obvious from the name “carbon film resistor” itself that this kind of resistor is made of carbon film. The carbon film is stored on the fired antecedent. This is really a decent sort of resistor, and that implies that it just gives an opposition esteem. The capability of the carbon film is to restrict the ongoing stream in the circuit. We can characterize carbon film resistors as: Carbon film resistor is a decent resistor. It utilizes a carbon film stored on a fired forerunner to restrict the progression of current.

The exactness of the opposition esteem given by this kind of resistor is because of the winding cut that is typically made into a slim film. This and other structural elements are talked about in the “Development” part of this article.

Presently this resistor has an exceptional image to show its schematic outline, you could think. Truth be told, this image is equivalent to the image for resistors, crisscross lines, or rectangular boxes (IEC standard).

While utilizing carbon film resistors in the circuit, we use “CR” to show. For instance, in the event that we utilized a 120 Kω carbon film resistor, we would compose it as CR120kΩ to address what is happening.

Carbon film resistors are built or manufactured using a deposition process. Its ceramic substrate is a carbon film. This carbon film restricts flow and is therefore an essential part of this resistance. It is for this reason that the resistor is named “carbon film resistor”. A hydrocarbon, such as methane or benzene, cracks at a high temperature of 1,000 degrees Celsius, where the ceramic carrier is broken. Since pure graphite (carbon) is used for distribution on the ceramic substrate without being combined with it, the noise generated by the carbon film resistor is very low. The role of the ceramic substrate is the heat or electricity of the insulator. Therefore, its existence enables this resistor to withstand high temperatures without causing great damage.

The Structure of Carbon Film Resistors

The two end covers displayed in the figure are really metal, and two associating wires made of copper are associated with the two finishes of these metal covers. We see that the carbon film is winding. It assists with getting a precise opposition from this obstruction. This helps increment the viable length of the resistor while decreasing the width of the resistor. The opposition esteem is changed by expanding or diminishing the length of the winding way. To safeguard the carbon film, it has an epoxy covering.

So How Does the Carbon Film Help Limit the Flow of Electrons?

This really relies upon the width of the carbon film layer. For higher opposition values, pick a slim layer. At the point when the width decreases, the space with the expectation of complimentary electrons to move decreases. Similarly, for low obstruction values, thick layers are picked. Since the more prominent the width, the more prominent the space with the expectation of complimentary electrons to stream, so the ongoing limitation is more modest than the limitation on the meager layer. Because of the utilization of unadulterated carbon, the resistor has a high bad temperature coefficient, in the scope of 2.5×10^-4ω/°C and – 8×10^-4ω/°C.

Advantages and Disadvantages of Carbon Film Resistors

Contrast carbon film resistors and carbon part resistors. The previous enjoys the benefit of low clamor. Contrasted and carbon piece resistors, it has lower opposition.

- It is easy to pocket because it is cheap cost.

It has a wide working reach, so it is broadly utilized.

- However, its high negative resistance coefficient makes the opposition effectively change with temperature. An expansion in temperature will decrease the opposition of the resistor, which is most certainly a colossal burden.

Application

This resistor can endure high temperature and high strain. They have viewed applications where these circumstances need as met. Its working temperature can arrive at 350°C and the voltage is 15 kV. Carbon film resistors are generally utilized in high temperature and high tension applications. It is generally utilized in high power supplies, X-rays, radar systems and lasers.

Summarize

The carbon film resistor is a proper resistor where the carbon film is utilized for its obstruction activity. Here, the statement interaction is utilized to fabricate and carbon film, typically cut into a winding, is stored on a ceramic substrate. This substrate goes about as a protector, assisting with enduring obstruction at high temperatures and high voltages. The width of the carbon film decides the worth of the obstruction. Assuming that the width is little, that is to say, a slight carbon film is utilized, the resistor gives a higher obstruction esteem. Essentially, on the off chance that a thick carbon film is utilized, the opposition worth of the resistor will be exceptionally low. What’s more, the twisting state of the carbon film can be acclimated to change the compelling length of the carbon film as per the obstruction esteem. The successful length is corresponding to the obstruction. Its negative temperature coefficient is exceptionally high. This is likewise the fundamental impediment of this sort of resistor, in light of the fact that its construction utilizes unadulterated carbon.