Sheet metal processing is the main component of metal processing in industrial production activities, and it is also an important process for forming sheet metal products. Its application fields are very wide, such as the metal casings of various household appliances, equipment, and instruments, billboards on the road, garbage bins, and the charging piles, car washing machines, and computer cases that we often use, all of which are finished products processed from sheet metal. The sheet metal processing industry has always been closely related to our lives and appears in almost all walks of life. Tianhong laser is one professional laser cutting supplier, dedicated in research and development of high power laser cutting machine which is suitable for metal sheet cutting.

With the development of modern industry, laser cutting technology has become a crucial advanced technology in the processing industry, and its application ratio is also increasing. At present, the application advantages of this technology in sheet metal processing technology are gradually emerging. It can optimize the cutting process and shaping of sheet metal workpieces, effectively reduce processing time, improve processing efficiency, and continuously strengthen the quality of workpiece processing, thus creating higher economic benefits for the sheet metal processing industry. Sheet Metal Laser Cutting Machine price is cheap and money-saving, saves the production time and money at the same time.

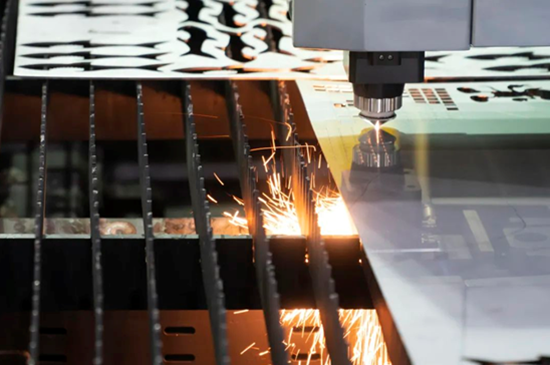

Principle of laser cutting technology in sheet metal processing

Laser is a kind of coherent light with great energy density and strong performance, and laser cutting technology is a processing technology derived from this, which is an advanced processing technology in sheet metal processing. Its main application principle is to focus a high-power, high-density laser on a certain point on the surface of the relevant material required in sheet metal processing, and then quickly and gradually converts light energy into thermal energy, and process the material. This technology has very advanced application advantages in sheet metal processing operations.

The advantages of laser cutting technology in sheet metal processing

First of all, the light spots focused on the laser beam are active and can be processed by fine and tightly, such as fine narrow seams and miniature holes.

Secondly, laser can cut almost all materials, including two -dimensional cutting or three -dimensional cutting of thin metal boards.

Secondly, laser processing does not need to use a tool, which is non -contact processing and has no mechanical processing deformation.

Therefore, with high efficiency, high energy and soft laser cutting technology, it has obvious advantages in accuracy, speed and efficiency, and has been very popular in the sheet metal industry. Some traditional difficult cuts or low -cut plates, after encountering laser cutting, the problem can be described as solved, especially the processing of some carbon steel plates, laser cutting has an unshakable position.

Finally, reduce sheet metal processing process and reduce production costs. In the sheet metal processing operation, almost all the boards need to be shaped on the laser cutting machine and perform a direct welding co -packaging. The dual optimization and reduction of labor intensity and processing costs, while promoting the optimization of the working environment, greatly improving the speed and progress of research and development, reducing mold investment, and effectively reducing costs; metal plate laser cutting machines compared to traditional metal plates compared to traditional metal plates. The cutting method is cost -effective.

Tianhong Laser is a professional fiber laser cutting machine supplier, the GDF series fiber laser cutting machine can cut metal sheet with high power.

Features:

(1) Auto -focus laser cutting head: No manual focus is needed; the software automatically adjusts the focus lens to achieve automatic perforation cutting of different thickness plates. The speed of the automatic focus lens is ten times than that of manual focus. There is a larger range of adjustment, the adjustment range is -10mm ~+10mm, and the accuracy is 0.01mm. It is suitable for different types of plates of 0 ~ 20mm. Both the collimating and focusing mirrors have water and cold radiator, which can reduce the temperature of the cutting head and increase the service life of the cutting head.

(2) High-power laser source: TH-GDF series high-power fiber laser of Tianhong laser cutting machine is IPG. The cutting capacity of metal materials such as stainless steel and aluminum is strong, and the cut thickness can reach 75mm.10000W high -power cutting, the cutting speed is faster, the accuracy is higher, and smooth surface cutting is achieved to meet the higher cutting quality requirements of users.

(3) Large format thick plate cutting: It can cut the medium thick plate of more than 20mm in batches, efficient and stable, and cut the 70mm ultra -thick plate to the limit. There are many conventional sizes to choose from, and can also be customized according to user processing. There are many types of processing materials, including stainless steel plates, carbon steel plates, copper plates, aluminum alloy plates, galvanized plates, electrolytic plates, titanium alloys, etc.

(4) Segmented smoke exhaust without pollution: The middle of the bed is separated by the beam and is separated by a small grid. At the same time, the segmented dust system is adopted. The corresponding ventilation door is automatically opened according to the position of the cut head, making the suction more concentrated and smoking smoother.

(5) Hydraulic lifting: The lifting dual exchange workbench is used to complete the exchange time less than equal to 20 seconds, which greatly improves processing efficiency and saves labor costs.

(6) Plate welding heavy workbench: The half -empty bed design, reducing the heating area, ensuring that the heat deformation is small, preventing the bed from deforming due to long -term high temperature, and effectively extending the service life of the equipment.