With the rapid development of science and technology, the role of fiber laser cutter machines in industrial manufacturing is becoming increasingly important and widely used. Compared with traditional cutting technology, fiber laser cutting machine has higher efficiency, higher cutting precision, cost saving and saving Cost, product quality, transportation cost, import and export cost, and other issues. It is difficult for customers to find reliable laser-cutting machine manufacturers.

So how to find good industrial fiber laser cutting machine manufacturers in China? I hope this article can help you.

Table of Contents

Composition of the fiber laser cutter

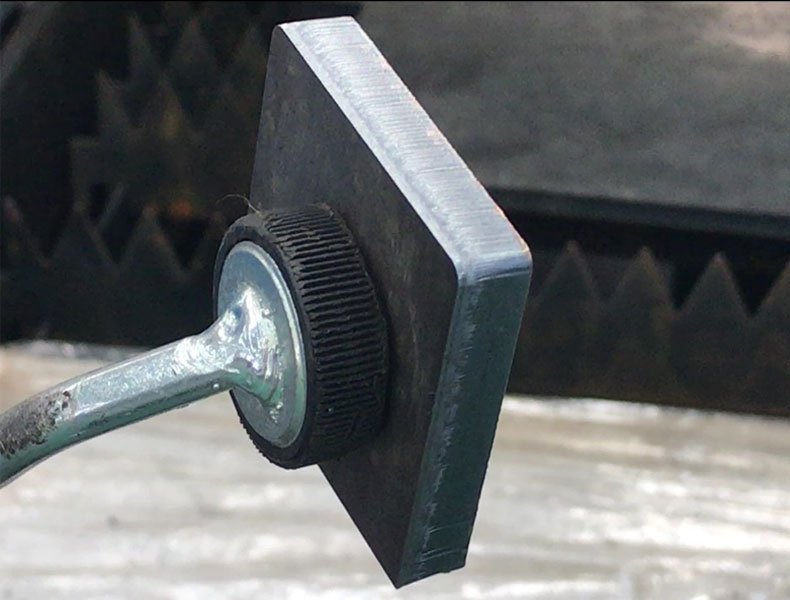

Fiber laser cutter machines mainly comprise fiber laser, cutting head, CNC motion system, bed, servo motor, blowing high-pressure gas, and other systems. Many parameters affect the laser-cutting process. Some of them depend on the technical performance of the laser and the machine, while others are variable.

How much does a cheap fiber optic laser cutter cost?

The market price of laser metal cutters for sale range from $10,680 to $156,800. To buy an affordable fiber laser cutting machine price, you need to understand the manufacturer’s size, customization capabilities, procurement of raw materials, machine production process, the manufacturer’s shipping capabilities, after-sales service capabilities, etc., to choose a cost-effective industrial CNC laser cutting machine suppliers, it is best to let the manufacturer first sample or field visits to the factory is better.

Industrial laser cutter delivery time, sampling time, delivery time??

The customer usually provides an industrial fiber laser cutter machine with a prototype, then one day to complete, in addition.

If OEM design of a metal laser cutting machine is required, then three days can be completed.

The delivery time of fiber laser cutting machines is different according to the production capacity of each factory. The delivery time is not equal, generally 21-30 working days, this depends on the specific situation.

How to judge the effect of the CNC fiber laser cutter machine?

Material Compatibility:

The effectiveness of a metal fiber laser cutter can also be judged by the range of materials it can cut. Cut the thickness of the metal sheet, the size of the bed, and the table.

Power and Wattage:

The power and wattage of the metal steel plate laser cutting machine are also very important. At present, the power on the market is 1000w, 1500w, 2000w, 3000w, 6000w, and the high power 12000w, 20000w 30000w carbon steel plate laser cutting machines. Higher power and wattage mean CNC laser cutters can cut thicker materials at faster speeds.

Cutting speed:

The cutting speed of a metal fiber laser cutter machine determines how quickly it can complete a job. High-speed laser cutting machines can complete more cuts in less time, increasing productivity and efficiency.

Cutting quality:

Cut quality can be assessed by checking the precision, smoothness, and accuracy of the cut. A high-quality laser cutter should produce clean and precise cuts without any jagged edges or burn marks.

User-friendliness:

The ease of use of a laser cutter can also affect its effectiveness. Is the operation interface friendly, how easy is it for novice users to learn, and whether the controls for importing graphics are easy to use

Pick the cheap fiber laser cutter.

To buy a large device such as a CNC laser cutting machine, you must choose a professional manufacturer to ensure the quality of the industrial laser cutter machine you buy. How to select a manufacturer must be a problem that many people begin to consider before purchasing the equipment. The next summary for you to select the laser cutting machine manufacturers need to pay attention to matters to help you select the laser cutting machine of your choice.

- 1. We need to know enough about the performance of the fiber laser cutter before selecting the fiber laser metal cutter, according to the different power fiber laser cutters for which material and thickness of the plate the fiber laser cutter to select.

- 2. In selecting industrial laser cutting machine manufacturers, we need to first understand the scale of the production base of laser cutting machine manufacturers and shipping cases for preliminary understanding. Choose a strong, with a certain scale of manufacturers. The follow-up equipment repair and maintenance is more secure.

- 3. How to pick the right industrial cnc fiber laser cutting machine in a short time? First, you can let the industrial laser cutter machine manufacturers sample and provide samples. You are satisfied before making a purchase.

- 4. Understand the after-sales guarantee system. Excellent laser cutting machine manufacturers have an after-sales guarantee system to protect customers’ interests. You can learn about this before you buy.